Advanced Material Systems

Advanced Material Systems

Unprecedented capabilities

in the harshest environments

Sporian has developed state-of-the-art, high-temperature ceramic

insulation technology. Sporamic™ is superior to other insulation due

to its high thermal radiation suppression ability. This material has

a unique combination of thermal and mechanical properties that make

it ideal for thermal protection systems. Sporamic™ has exceptional

oxidation and corrosion resistance with low density and high

strength. It exhibits vibration resistance, very low moisture

absorption, and low friability. Contact us directly to learn more.

|

Sporamic™ Advanced MaterialsUnmatched thermo-mechanical

properties and durability up to 1600°C

Sporamic Brochure (1.7MB PDF) Key Features Include:

|

|||||||

|

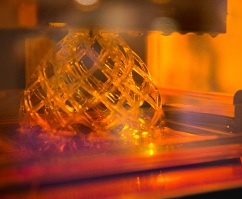

3D Printing of Advanced MaterialsPolymer derived ceramics are being

developed at Sporian for use as UV curable 3D printing

materials, providing an additive manufacturing pathway towards

multifunctional hot structures for utility in atmospheric entry

vehicles. Sporesin™ PDC precursor materials make it easier to

create UHT ceramic materials. |

|||||||

|

||||||||